One of the things I love about building instruments is, I am compelled to hustle for odd jobs to keep the bills paid. The variety of work is key to my ability to maintain a mostly positive outlook. If I can function as a Swiss Army Knife in a given situation, I'm happy as a clam.

One of the things I do from time to time is install a 3M product called Dinoc. The manufacturer refers to it as an Architectural Film. Honestly, it's a lot like the contact paper that your granny used to line her cupboards. It can be applied to a variety of substrates, including automobiles, and the several hundred styles offered can add a lot to the look of a room. I spent the last week driving from Minneapolis to Chicago and then just making figure-eights through the lower mid-west for a few days.

The client was Marriott Hotels Fairfield Inns. We were to complete some recent obligatory renovations by wrapping the elevator and the nine swimming pool windows at three locations. One thing I noticed about the decor at Fairfield Inns is, the colors were well chosen. Everything is tied together and when we finished the first elevator, it was obviously meant to be.

Note the yellow of the entry walls and how it is repeated ever so lightly in the Indian Rosewood style Dinoc inside the car. There is "open grain" on the visible surface of the vinyl sheet which adds a certain believable texture. This was the cleanest install I have ever done.

Note the yellow of the entry walls and how it is repeated ever so lightly in the Indian Rosewood style Dinoc inside the car. There is "open grain" on the visible surface of the vinyl sheet which adds a certain believable texture. This was the cleanest install I have ever done.

They start out looking like this! This look was cutting edge when it was originally installed 40 years ago.

They start out looking like this! This look was cutting edge when it was originally installed 40 years ago.

It took almost eight hours to prep the car and wrap this interior. There are cross-grain seams behind each handrail and a bolt/cylinder connector for each twelve inches of rail. This means grain matching the cut (not a big deal, actually) and making cutouts in the proper place for every connector and then trimming each one very cleanly to make it look like the most natural thing in the world. The second half of that really is a big deal and takes lots of time and patience.

The finished product. Ta-da! We don't do floors and so someone came along, perhaps, and fitted a nice piece of rug here. I streamlined the process and manage to shave off two hours from this installation. It was definitely easier to do the job without the carpet on the floor.

The finished product. Ta-da! We don't do floors and so someone came along, perhaps, and fitted a nice piece of rug here. I streamlined the process and manage to shave off two hours from this installation. It was definitely easier to do the job without the carpet on the floor.

Kiss 'em goodbye! The windows were a cakewalk after dealing with an elevator. All the employees we came across thought this was a bad idea. I directed them to the corporate designer. This was the first time I 've put this stuff in. Nice to have another trick up my sleeve. Anyone want their auto windows frosted?

Kiss 'em goodbye! The windows were a cakewalk after dealing with an elevator. All the employees we came across thought this was a bad idea. I directed them to the corporate designer. This was the first time I 've put this stuff in. Nice to have another trick up my sleeve. Anyone want their auto windows frosted?

It was nice to get back home and lay into some building. I have some shiny bits on order that are holding up the process on the uke I'm building. Needing to make some progress on it, I moved to another project; finishing the fingerboard.

The bound fingerboard from the kit comes pre-slotted for frets. This is nice because I am not currently set up for this task. However, the surface had no radius and indeed, was not even sanded. Lucky for me, I know how to do this. Notice the two brownish streaks on the sanding block paper. When those two lines connect in the middle of the block, the radius is completed.

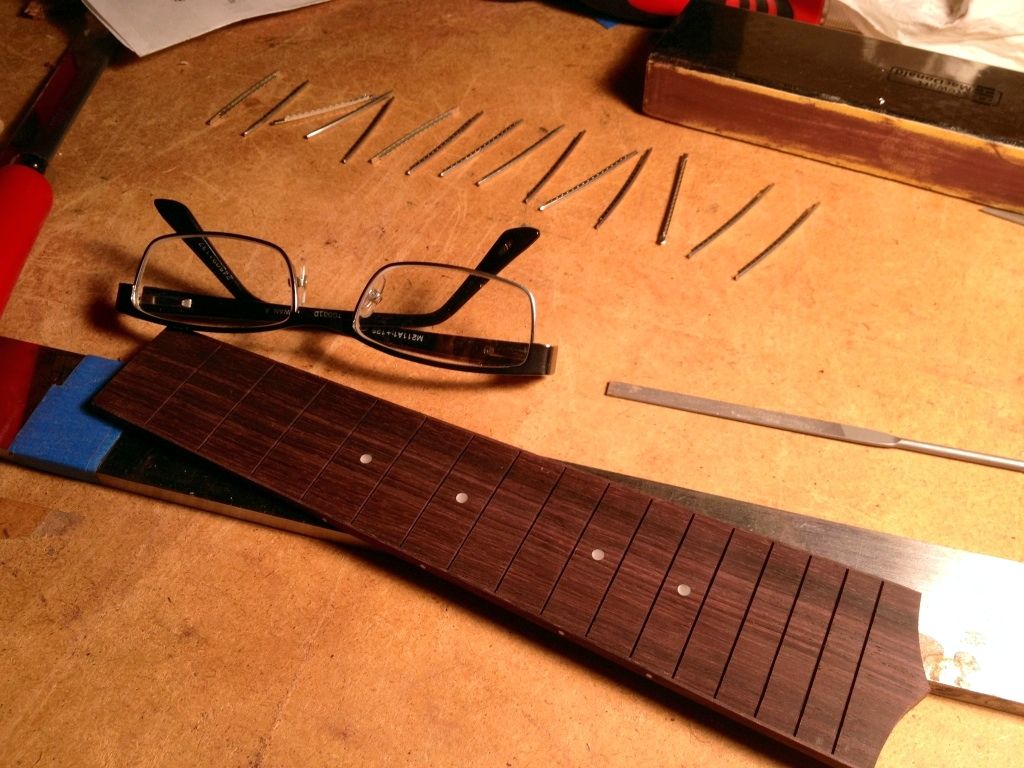

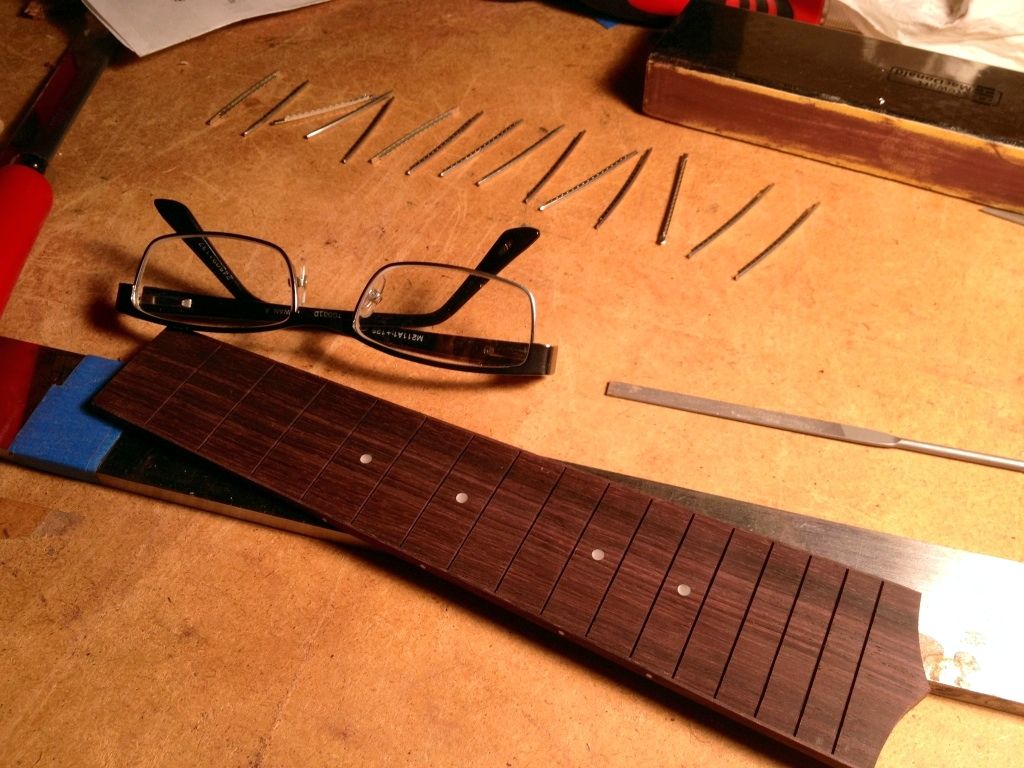

I cut the frets and notched each tang to fit in over the binding. This is another long, tedious job but it has to be done. Time to pull out the reading glasses...

I cut the frets and notched each tang to fit in over the binding. This is another long, tedious job but it has to be done. Time to pull out the reading glasses...

After a bit more prep to the fingerboard, the fret press does a beautiful job of seating the fret wire. Because of the detailed prep work, very little leveling is required. A little filing to the fret ends and... presto! This sucker is ready to go.

After a bit more prep to the fingerboard, the fret press does a beautiful job of seating the fret wire. Because of the detailed prep work, very little leveling is required. A little filing to the fret ends and... presto! This sucker is ready to go.

Now it's time for a little mando work.

I moved on to the final shaping of the soundboard. With the fingerboard off of the neck, I can get my finger planes into the the highly sculpted areas at the top of the body. I love this work. I could do it for hours. That's good, because it takes a couple to get this far. Just a bit farther to go, but it's bedtime.

I moved on to the final shaping of the soundboard. With the fingerboard off of the neck, I can get my finger planes into the the highly sculpted areas at the top of the body. I love this work. I could do it for hours. That's good, because it takes a couple to get this far. Just a bit farther to go, but it's bedtime.

After a nice session, it's good to wind down with a little bit o' guitar. This is the first time I've tried posting video. If the player sucks, let me know. I'll put 'em on youtube in the future. Cheers!

One of the things I do from time to time is install a 3M product called Dinoc. The manufacturer refers to it as an Architectural Film. Honestly, it's a lot like the contact paper that your granny used to line her cupboards. It can be applied to a variety of substrates, including automobiles, and the several hundred styles offered can add a lot to the look of a room. I spent the last week driving from Minneapolis to Chicago and then just making figure-eights through the lower mid-west for a few days.

The client was Marriott Hotels Fairfield Inns. We were to complete some recent obligatory renovations by wrapping the elevator and the nine swimming pool windows at three locations. One thing I noticed about the decor at Fairfield Inns is, the colors were well chosen. Everything is tied together and when we finished the first elevator, it was obviously meant to be.

Note the yellow of the entry walls and how it is repeated ever so lightly in the Indian Rosewood style Dinoc inside the car. There is "open grain" on the visible surface of the vinyl sheet which adds a certain believable texture. This was the cleanest install I have ever done.

Note the yellow of the entry walls and how it is repeated ever so lightly in the Indian Rosewood style Dinoc inside the car. There is "open grain" on the visible surface of the vinyl sheet which adds a certain believable texture. This was the cleanest install I have ever done. They start out looking like this! This look was cutting edge when it was originally installed 40 years ago.

They start out looking like this! This look was cutting edge when it was originally installed 40 years ago.It took almost eight hours to prep the car and wrap this interior. There are cross-grain seams behind each handrail and a bolt/cylinder connector for each twelve inches of rail. This means grain matching the cut (not a big deal, actually) and making cutouts in the proper place for every connector and then trimming each one very cleanly to make it look like the most natural thing in the world. The second half of that really is a big deal and takes lots of time and patience.

The finished product. Ta-da! We don't do floors and so someone came along, perhaps, and fitted a nice piece of rug here. I streamlined the process and manage to shave off two hours from this installation. It was definitely easier to do the job without the carpet on the floor.

The finished product. Ta-da! We don't do floors and so someone came along, perhaps, and fitted a nice piece of rug here. I streamlined the process and manage to shave off two hours from this installation. It was definitely easier to do the job without the carpet on the floor. Kiss 'em goodbye! The windows were a cakewalk after dealing with an elevator. All the employees we came across thought this was a bad idea. I directed them to the corporate designer. This was the first time I 've put this stuff in. Nice to have another trick up my sleeve. Anyone want their auto windows frosted?

Kiss 'em goodbye! The windows were a cakewalk after dealing with an elevator. All the employees we came across thought this was a bad idea. I directed them to the corporate designer. This was the first time I 've put this stuff in. Nice to have another trick up my sleeve. Anyone want their auto windows frosted?It was nice to get back home and lay into some building. I have some shiny bits on order that are holding up the process on the uke I'm building. Needing to make some progress on it, I moved to another project; finishing the fingerboard.

The bound fingerboard from the kit comes pre-slotted for frets. This is nice because I am not currently set up for this task. However, the surface had no radius and indeed, was not even sanded. Lucky for me, I know how to do this. Notice the two brownish streaks on the sanding block paper. When those two lines connect in the middle of the block, the radius is completed.

I cut the frets and notched each tang to fit in over the binding. This is another long, tedious job but it has to be done. Time to pull out the reading glasses...

I cut the frets and notched each tang to fit in over the binding. This is another long, tedious job but it has to be done. Time to pull out the reading glasses... After a bit more prep to the fingerboard, the fret press does a beautiful job of seating the fret wire. Because of the detailed prep work, very little leveling is required. A little filing to the fret ends and... presto! This sucker is ready to go.

After a bit more prep to the fingerboard, the fret press does a beautiful job of seating the fret wire. Because of the detailed prep work, very little leveling is required. A little filing to the fret ends and... presto! This sucker is ready to go.Now it's time for a little mando work.

I moved on to the final shaping of the soundboard. With the fingerboard off of the neck, I can get my finger planes into the the highly sculpted areas at the top of the body. I love this work. I could do it for hours. That's good, because it takes a couple to get this far. Just a bit farther to go, but it's bedtime.

I moved on to the final shaping of the soundboard. With the fingerboard off of the neck, I can get my finger planes into the the highly sculpted areas at the top of the body. I love this work. I could do it for hours. That's good, because it takes a couple to get this far. Just a bit farther to go, but it's bedtime.After a nice session, it's good to wind down with a little bit o' guitar. This is the first time I've tried posting video. If the player sucks, let me know. I'll put 'em on youtube in the future. Cheers!

No comments:

Post a Comment